Today we’re talking with George Chevalier, the man in charge of Marketing and Communications at Princeton Tec out of Trenton, NJ.

Can you give 50 BUILT readers some background on yourself and the events that led up to starting Princeton Tec?

Bill Stephens started Princeton Tec in 1975, in the back room of their Princeton, NJ dive shop. To kick things off, they dreamed up and built the first automatic dive timer. Next, the PTEC product line expanded to include everything a diver could need, from watches to gauge consoles, flashlights and even replacement mask and fin straps. They were ahead of the curve with flashlights, and eventually PTEC transitioned into a lighting company. Today, we design and manufacture lights for the Outdoor, Industrial, Tactical, Bike and of course SCUBA markets. While Bill has retired, his son and grandson are integral to the company today.

What has the road been like sourcing American made components for your line?

Because Princeton Tec has been around for nearly 40 years, sourcing American made components is baked into our process. In many cases, we have long standing relationships with our suppliers. In one case, however, the demise of a supplier of a very specific bulb necessitated creating a whole new light design rather than sticking with our proven model. I suppose the point is that sometimes the road is a little bit longer, but there is always a way.

Has Princeton Tec always produced their product in America? If so, was that a conscious decision or was it a result of other factors? If not, what decisions influenced that and what were the results of that experiment?

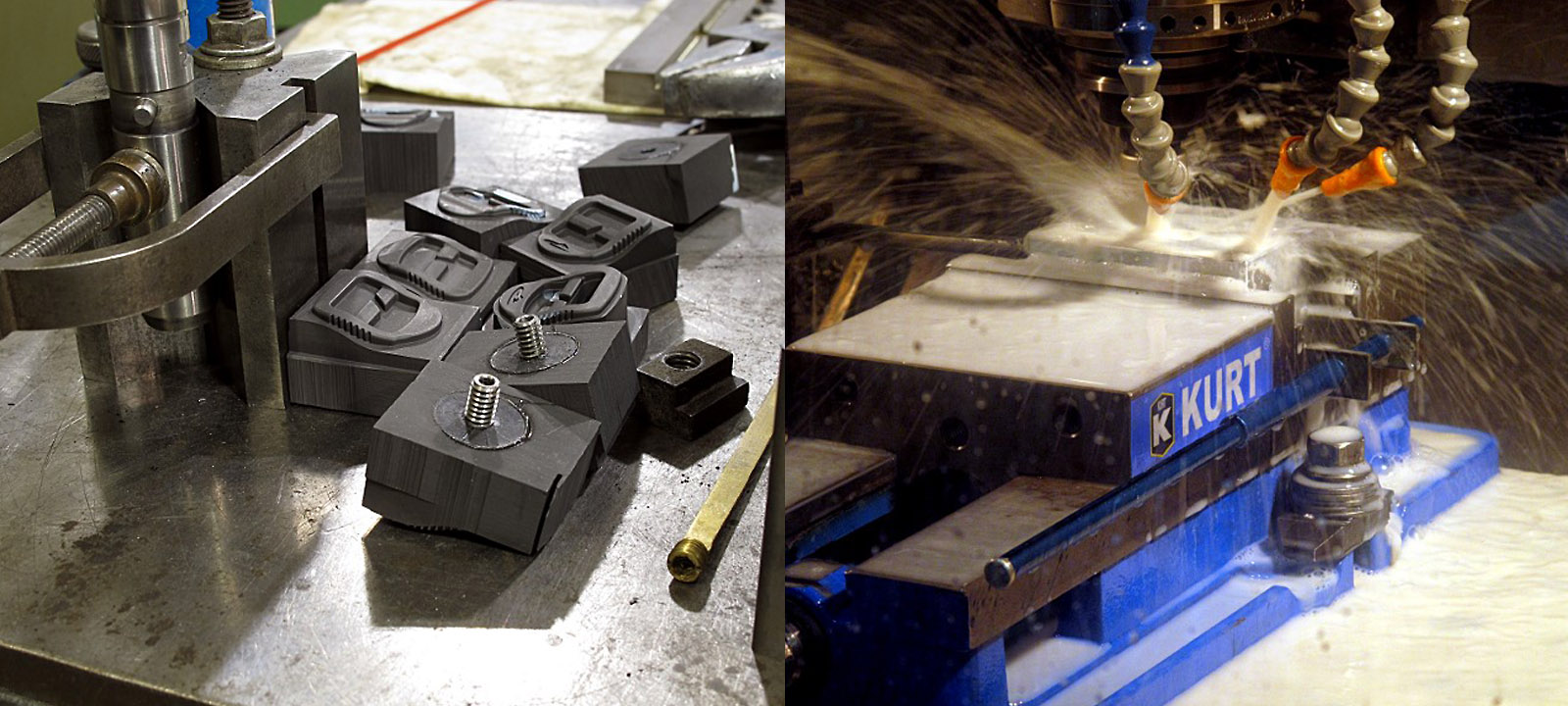

We have always been an American manufacturer. PTEC began by producing our products in the US, as was fairly common in the mid 70’s. This has been an advantage, as some markets demand domestic manufacturing. For instance, we were able to expand into the tactical space due in part to our domestic manufacturing capabilities. As the importance of domestic manufacturing continues to grow in the consumer market, the public chooses PTEC lights on that basis, as well as our designs and excellent customer support.

Those who are very familiar with PTEC know that we began importing some of our lights during a period when our own manufacturing capabilities were maxed out. It was a learning process. We were not able to enjoy the same hands on approach as with a product made in our factory. Likewise, the inherent lead times could be challenging for an organization accustomed to running our own factory. Needless to say, that experiment is coming to a close as we work to move all production back under our own roof. We have expanded our facilities, so we once again have the needed capacity here in New Jersey!

How does having a manufacturing facility impact your relationship with Trenton, NJ? And how does your relationship with Trenton influence your decisions with regards to your company and its employees?

PTEC is based in an area that was a manufacturing powerhouse from the 1800’s and into the 1970’s. Like so much of the US, the economy here is just not as strongly focused on industry anymore. With that said, we are very proud to keep a part of the legacy alive by creating jobs for approximately 200 local folks. Some families have two generations working here, and members of the third generation come in to help out and earn some spending money during breaks from school. As a result, there is a bit of a feeling that we are a big extended family.

Why is it so important for Princeton Tec to market the fact that they are ‘American Made?’

Americans are now more conscious about our purchases than we have been in a long time. Everytime PTEC visits a different part of our country, we see and hear the same: people are surprised and impressed that we make our products in the US and have a significant workforce of humans (not a room full of machines!) building our lights. This is always a positive point that cements the brand as the “go to” for personal lighting products like headlamps and flashlights.

If you could tell our readers one factor that is the greatest threat or advantage to keeping things made in America, and allowing companies like Princeton Tec to succeed, what would it be?

The greatest threat comes in the form of cost. Competitors with a cost advantage can sell a product at a lower price point. This is the result of many different factors from the design stage all the way through to manufacture and distribution of a product.

On the other hand, by manufacturing in our own facilities, we gain the advantage of being able to make changes to react to broad market and even specific customer needs more quickly than the competition. Of all the factors that could contribute to the success of American companies, well informed consumers are probably the most important one. There is a constant need to illustrate just how much of an impact we can have by purchasing domesitcally made products.

Do you have any final thoughts that you’d like to leave with our readers?

People are so used to everything in the marketplace, (particularly products made of plastic) being imported from Asia. It always pays to flip a package over to find out the origin of whatever you’re buying. (Though 50 Built fans already know that!) Domestic manufacturers will typically start with higher quality materials. Being able to call and speak with another human should you have any questions is very valuable. Finally, think about the families and communities that depend on the small businesses they work for or run to earn a living.

We’ve had a great number of fans and supports for nearly 40 years, and hope that we can keep doing what we know best for many more!

Thank you so much, George, for your time and perspective!