1. American Trench, Wool and Cotton Scarf 2. American Trench, Cashmere Blend Fair Isle Sock 3. Best Made Co., The Belgian Dart Set 4. Topo, Daypack 5. J.W. Hulme Co., Valet Tray and Hamline Pocket Journal 6. Best Made Co., Shawl Neck Sweater Coat 7. Whiskey and Rum Making Kit 8. Best Made Co., Front Loading Tool Box 9. One Forty Three, Plywood Guitar Hook 10. Mitchell Bat Company 11. Reclaimed Redwood Bluetooth Speaker

Today we’re talking with Bron Heussenstamm of Alex Maine. Can you tell us a little about yourself and how Alex Maine came to be? As for my experience, I grew up in my parents’ surf shop, Newport Surf & Sport, Huntington Surf & Sport. I used to be the kid who would grab peoples’ ankles under the clothes. It’s just been my entire life, you know?, I’ve always been in the clothing and retail sales (industry). So it’s something that I knew that I’d always want to get into. I went to USC and I was an entrepreneurship major. I started a couple businesses, didn’t really go the way that I was hoping with the partnerships and whatnot. So I took a job at Sanuk, doing their PR for a year. They’ve just been acquired by UGG, so that’s a good step for them. I knew that I wanted to…Continue Reading

Today we are talking with the fine folks at Northern Grade, a pop-up market of American Made products. Can you give 50 BUILT readers some background on yourselves and how Northern Grade came to be? Well being based in Minnesota, we are surrounded by brands like Red Wing and Duluth Pack who represent the authentic heritage brands. We thought we should do something to celebrate them and promote their historical significance. We also saw a lot of men in this area who did not know where to shop for premium American brands. How has Northern Grade evolved from when it started in 2009? We have grown from an event that had about 600 people at the first one, to 3000 at our last. We still have about 20 vendors. We like to keep things in scale with our venue, Architectural Antiques. Has the Made Local/USA always been the…Continue Reading

Today we are talking with Jen Guarino, CEO of J.W. Hulme. J.W. Hulme has been making quality goods in Minnesota since 1905. Can you give 50 BUILT readers some background on how J.W. HULME Co. came to be, what has changed over the lastcentury, and your product offerings? John William Hulme founded J.W. Hulme Co. in 1905 as a tent and awning maker. By 1917 Hulme was making tents for American soldiers fighting the Great War. After World War I, our company began to apply its fastidious approach of purposeful design and construction towardsproducing awnings for the homes of St. Paul’s elite. Such was the demand for Hulme’s hand craftsmanship that the company’s product offering grew over time to include leather and canvas sporting bags and accessories. Distinctive Hulme bags became a must-have for the serious outdoor sportsman. As J.W. Hulme flourished it concentrated solely on making bags, including private label…Continue Reading

Today we are talking with Tony Patella of Tellason. Tellason is a premium denim company founded by Tony Patella & Pete Searson in San Francisco, CA. What was the catalyst for starting Tellason? Pete and I had been in the apparel industry for twenty years each in various forms — sales agents, sales directors and in my case, also as a partner in a San Francisco-based denim brand in the 1990s. It really came down to our shared passion for denim and durable goods and our desire to do something of our own. We are a two-person operation. We have interns on occasion, but all of the design, distribution, customer service and sales management is handled by the two of us. Our studio is in Sausalito, California and the factory that makes our products is right across the Golden Gate Bridge in San Francisco. The factory makes products for several…Continue Reading

Today’s product review is on Field Notes. If you ever find yourself in need of a pocket sized memo-book, look no further. Co-produced by Coudal and Draplin, these are well designed and useful for any human, young or old, tall or small. Field Notes are made with quality materials, printed in the USA, and have an assortment of colors/themes that sets the mood for every occasion; and if there isn’t an occasion make one up and buy them anyways. So far I’ve ‘tested’ the State Fair series, National Crop series, the recent baseball series and several standard issue kraft brown gems. Memo-book comes in the options of Plain, Ruled or Grid, white paper, and all have a sturdy card stock cover. The interior 48 pages are thick enough to write in pen, without it bleeding through and the grid lines are visible but not overbearing. The insides of the covers are…Continue Reading

Today we are talking with James Murray, Executive Director of Product Development and Design at Simon Pearce. Simon Pearce is an American glass and pottery company from the state of Vermont. Can you give 50 BUILT readers some background on yourself/your role and the history of Simon Pearce? My background is building products with glassmakers and ceramic companies, many of them in Europe. I worked with factories throughout Italy, Portugal, Poland, Czech Republic & Slovakia where the same traditions in craft are upheld by family owned businesses. With 11 years at Macy’s/Federated, and 5 years with Bed, Bath & Beyond, working in tabletop, and a variety of home categories, I witnessed the decline of business with these European factories and just over 2 years ago, looked into how I could dedicate design efforts to promoting manufacturing in America. I was familiar with Simon Pearce, (as my wife is from…Continue Reading

Today’s interview is with Dave Schiff, partner & chief creative officer of Made Movement, a two part initiative for promoting American-made. Can you give 50 built readers some background on yourselves and the events that lead up to starting made? Scott, john and i were all running large departments at crispin porter and bogusky. Scott was director of digital, john was director of design, and i was executive creative director. Scott was one of the guys who invented nike plus. John helped turn around dominos. I launched coke zero. We loved our jobs and we were generously compensated, but something was missing. We needed a mission. What was the catalyst for starting made? The catalyst was actually a single statistic: if americans buy just 1 percent more stuff made in america, it will create 200,000 jobs. For three guys who’ve spent their entire careers convincing people to buy things,…Continue Reading

Today’s interview is with Tim Andis, founder and CEO of Liberty Bottleworks based in Yakima, Washington. Liberty Bottles are the only metal bottles made in the USA. Can you give 50 BUILT readers some background on yourself and the events that lead up to starting Liberty Bottleworks? The catalyst for starting Liberty Bottleworks was REI. I had been selling another brand of water bottles to REI and they asked me to find a domestic supplier. They were tired of foreign suppliers who couldn’t fulfill reorders based on trends in the current season and the excessive freight costs and delays from overseas shipments. I thought, okay, I’ll go find one, but to my surprise nothing existed. Long story short and a lot of hard work later, I decided to build a factory in the US to help customers like REI have a domestic supplier who was flexible and cared about their business…Continue Reading

Trying to find your dog a toy that’s made in the USA isn’t easy, but there are options. Kong doesn’t make all of their toys in the USA, but one that is, is their Classic toy. For the last 30 years the classic Kong has been among the first toys purchased for a new dog or puppy. It’s offered in 6 different sizes and densities. With a size and softness for every dog, it makes the perfect entertainment toy, chew toy and you can stuff it with treats to keep your pup busy for hours. We have two Kongs for our dog that have last over 1.5 years so far, without major signs of wear. She tore through her puppy Kongs once her adult teeth came in, but it was obviously time to to upgrade to the harder rubber anyways. It’s her go to toy to play fetch or tug,…Continue Reading

Today’s interview is with one of the founders from We Are Runts (WAAR), Michael Quinones. Michael and Matt Davis started WAAR as a mission to bring Made in the USA to market with influences pulled from the surf, skate and motorcycle culture. They have dedicated themselves to bringing an affordable, 100% USA made, product to the consumer. Can you give 50 BUILT readers some background on yourselves and how WAAR came to be? Matt Davis & I both have worked in the action sports and contemporary apparel market for about a decade now. All the brands that we have been apart of were developed and manufactured overseas with the intent on being more or less volume driven. We saw the issues of developing and producing overseas as startup companies. The constant ‘bait and switch’ that would happen with production, poor quality, and generally zero accountability for the issues at hand…Continue Reading

Vapur is a water ‘anti-bottle’ company located in Westlake Village, California. They are on a mission to educate the consumer and support the movement away from bottled water. They have statistics on their website, and they donate/fundraise for Drop of Hope & the Anti-Bottle Project, all in the name of good, clean, water. Their product is unique in that it is flexible, reusable, eco-friendly and made in the USA. These ‘anti-bottles’ are also freezable, dishwasher-safe and BPA-free. They offer three different anti-bottles: Reflex, Runaway & Element. Today we’re reviewing the .7L/ 23 oz Element. What an awesome product. It really provides a stylish and easy-to-use container for your favorite thirst quencher. The .7L Element retails for $11.99. This is truly a steal for such a functional, USA-made product. When it’s full, the container stands on its own, no awkward tipping or any sign of being unstable. When it’s empty, it can be rolled…Continue Reading

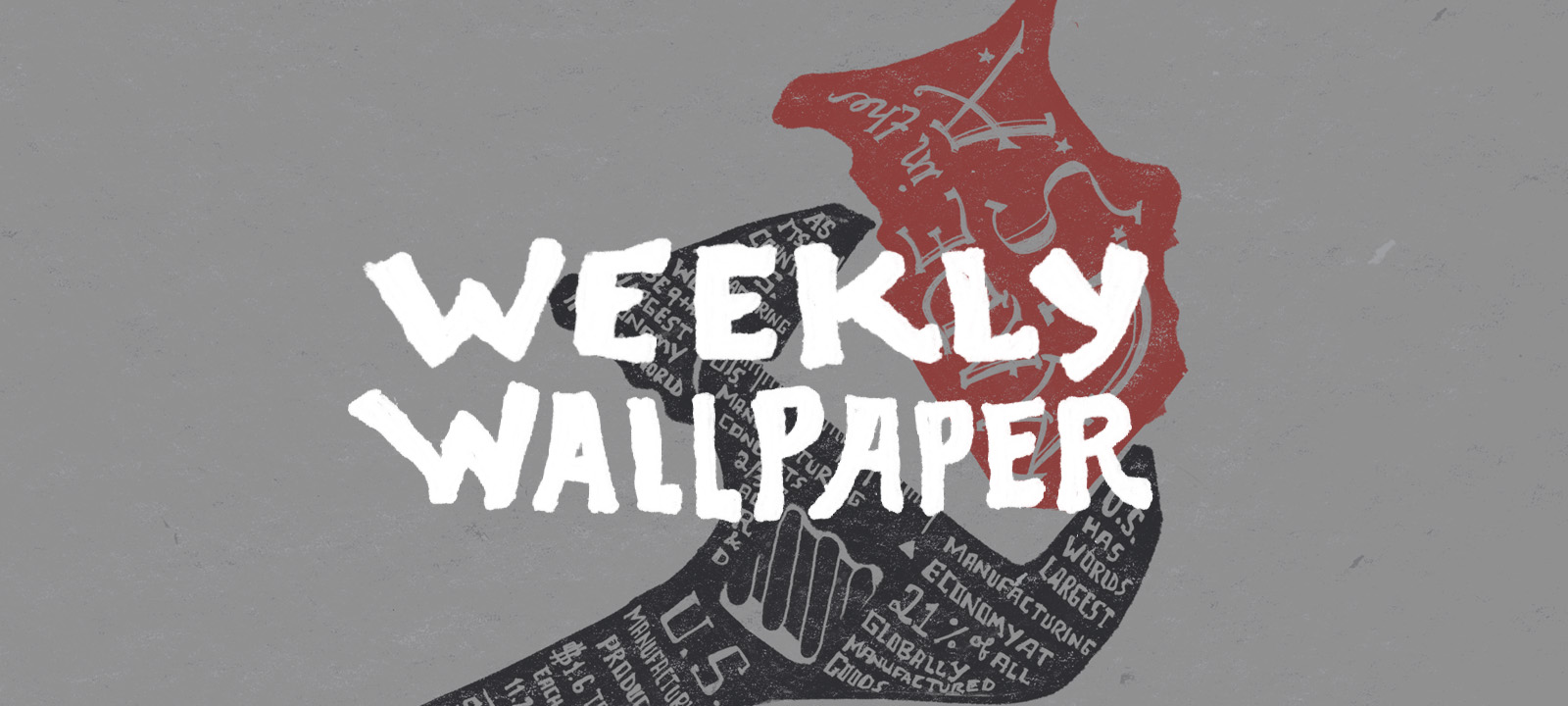

This week’s wallpaper highlights an overall picture of manufacturing in the USA and the positive factors our American workers can offer. Available in 4 different sizes for your computer or iphone. Free to download. Also available as a poster for purchase in the shop. STANDARD SCREEN | WIDESCREEN SCREEN | HD SCREEN | iPHONE